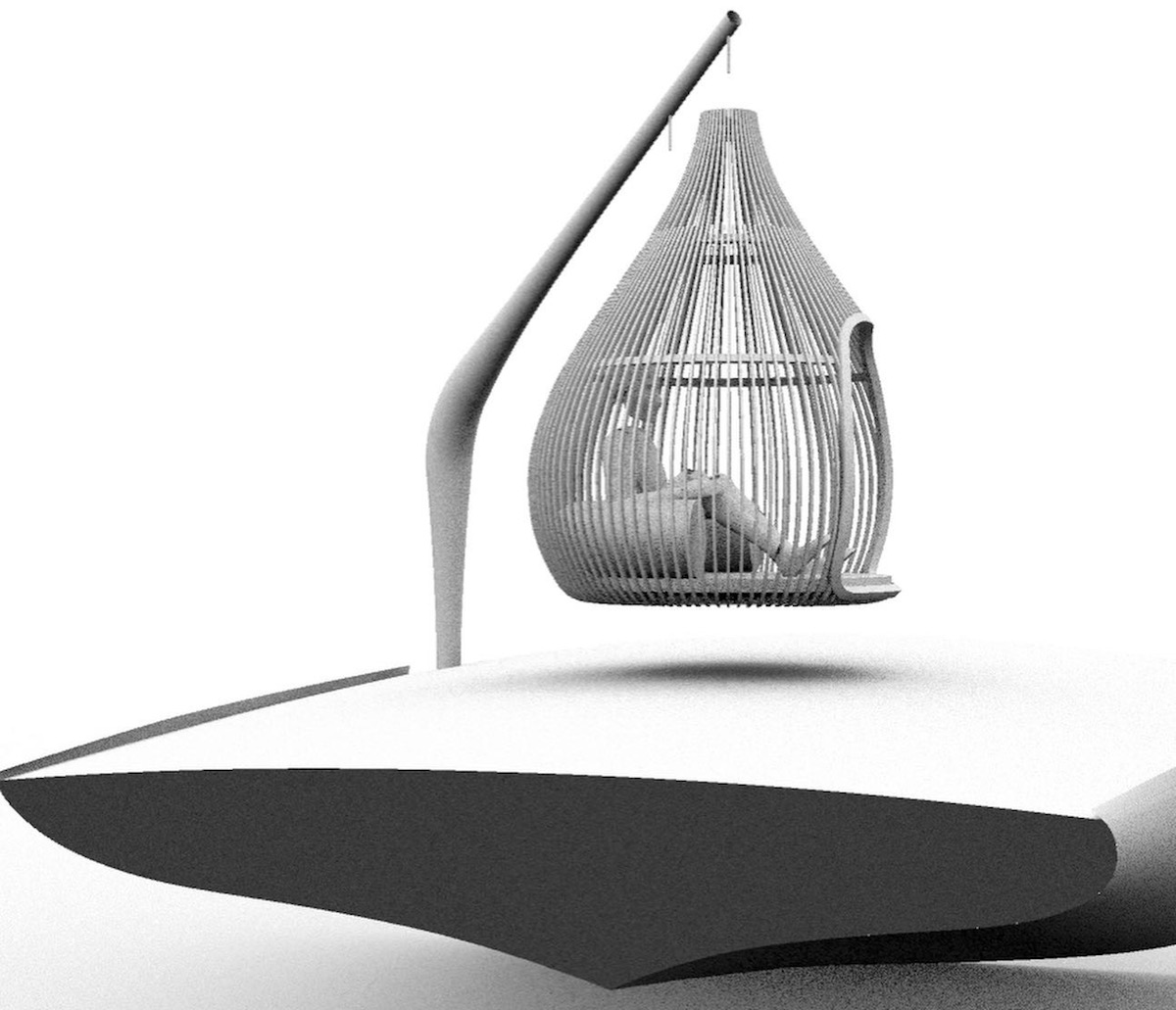

With the Summer time holidays in sight, I’m wanting ahead to spending just a few weeks within the Mediterranean with a number of sunshine and boat journeys to lovely seashores. It’s the proper space to sit down, chill out and benefit from the gorgeous views. Because of this it’s so becoming that the Palma-based designer, Robert Coleby, designed the attractive Teardrop chair.

He teamed up with Cutr, a market that connects designers and creators with woodworkers, to carry the chair from idea to actuality. Given its advanced design, Coleby bumped into issues, however partnering with Cutr helped him overcome these challenges rapidly and effectively.

Beneath I’ll share extra concerning the idea of the Teardrop chair and a peek into Cutr. Should you’re a designer, architect or product maker eager to make something from furnishings, cupboards, tiny homes and extra, you’ll wish to test them out! I, myself wish to work with Cutr sooner or later.

Cutr – From design to manufacturing

As a woodwork manufacturing service, Cutr helps get your merchandise designed, constructed and delivered. Offering design help, prototyping, and serial productions subsequent to very versatile fee phrases . They assist you discover the most effective value, lead time and high quality and match you with certainly one of their community companions based mostly in your manufacturing wants.

As a result of design and manufacturing go hand in hand, Cutr can also be the proper associate for the manufacturing companions who could make what a designer creates. As a market for woodwork, Cutr helps clients discover the proper producer. “Our software program and crew do a whole lot of work upfront to make sure our companions get well-scoped, error-checked initiatives able to go. We at all times pay upfront and supply the phrases they need.” Cutr says.

The Teardrop chair

The Teardrop chair was dropped at life by Robert Coleby, a craftsman residing in Palma, with a ardour for cupboard and furnishings making and a wealth of expertise in boat constructing at Spirit Yachts.

The idea for the chair was born from the yacht’s inside, which embraces clean, natural shapes and avoids any sq. or upright components beneath deck. Holding this distinctive aesthetic in thoughts, the shopper shared an idea sketch. Whereas the design seemed implausible, Robert realized some main changes had been essential to make sure the chair’s performance on a transferring yacht.

It wanted to rotate and transfer freely in all instructions to resist the pressures from any waves and movement. And to realize the chair’s proportions, the present davit didn’t present sufficient peak from the deck, and an extended carbon davit was wanted. The chair needed to be designed to interrupt into sections for straightforward storage within the yacht’s lazarette throughout crusing.

Working intently with Cutr all through the challenge

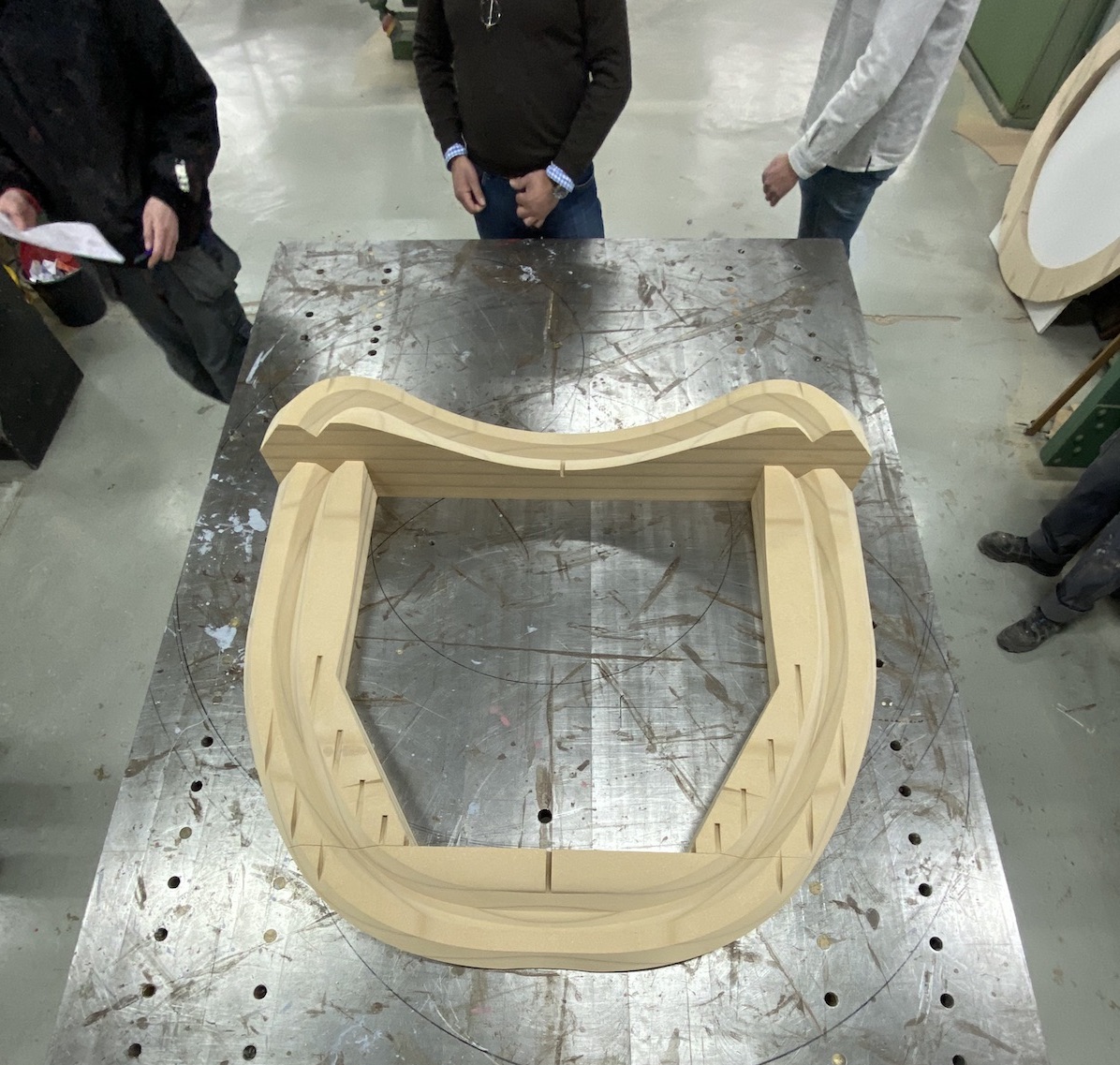

Along with naval architect Neal Pawson, an professional in CAD, they refined the size and curves of the chair’s opening hoop, placing a stability between practicality and aesthetics. The manufacturing part encountered some hurdles alongside the best way. The advanced mould required for the opening hoop necessitated a specialised 5-axis CNC machine, which was difficult to seek out regionally.

Robert obtained a advice to attach with Cutr. Their inner design crew labored with Robert on the difficult temporary and located an appropriate manufacturing associate after shortlisting just a few potential companions. They helped to keep away from a probably expensive setback because the specialist machine operator on the first manufacturing associate give up. Cutr rapidly understood his wants and located the manufacturing associate Kleizen, a improvement associate in advanced types, guaranteeing the challenge’s continuity.

Ending the chair and searching again on the proces

Ending the chair and searching again on the course of

The ultimate mould arrived and assembled completely and was able to go. The subsequent problem was establishing the chair’s advanced opening (door). Every hoop is made out of seven layers of teak, and solely in a position to glue one layer at a time to make sure that all of the joints are tight and the timber adopts the right form on the mould. This was a time-consuming course of. The 96 battens that fashioned the chair’s vertical items had been meticulously crafted by laminating teak strips collectively and skilfully clamping them onto moulds.

Trying again on the making of the Teardrop chair, Robert says that it has been a labour of affection for 12 months and is his proudest design achievement. He’s delighted concerning the consequence and his partnership with Cutr to beat the challenges.

The ultimate door/opening for the Teardrop chair

Written in collaboration with Cutr